– Feature Article – Shop Talk: Drilling Small Holes

– Pinewood Derby Car Showcase

– Q&A

Shop Talk: Drilling Small Holes

By Randy Davis

If your pinewood derby race rules allow axle holes, then you have likely drilled the holes using a drill press, or a Pro-Body Tool or Pro-Axle Jig. For Cub Scout axles, a #44 bit1 is recommended, while a 3/32 inch bit is typically used for Awana axles. For a few other kits, a #43 bit works well. But regardless of the bit size, have you considered the best type of bit to use? The type of bit, as well as the technique used, both affect the accuracy of the result. In today’s shop talk we will discuss the various types of drill bits and some techniques to help improve accuracy.

Small Drill Bit Types

The most common small drill bit types are high-speed steel (HSS), carbide, and cobalt.

HSS

HSS drill bits are flexible and strong. They are inexpensive and used where long-term durability is not important. Most drill sets are HSS. The flexibility of the HSS bit is helpful in minimizing broken bits, but the flexibility is a hindrance where accuracy is concerned. For drilling axle holes with a Pro-Body Tool/Jig, a HSS bit is fine, as the tool minimizes the flexing of the bit; but when drilling holes with a drill press the flexibility really hinders accuracy.

Carbide

Carbide drill bits are extremely hard, so flexing is virtually eliminated. However, because they do not flex, they are prone to breakage if careful technique is not applied. Carbide bits often come with a shank larger than the bit. So if you purchase one, make sure to get one that is long enough to drill axle holes – many Carbide bits are too short for drilling axle holes.

(Source: www.carbidespecialties.com)

Cobalt

Cobalt bits2 are also extremely hard, so flexing is virtually non- existent. But Cobalt bits have a big advantage over HSS and Carbide bits — Cobalt bits have a “split point” tip that is specifically designed to keep the bit from “wandering” (i.e., not entering the wood at the location you want).

Wood is a relatively soft medium, but it is not consistent in density. Depending on the grain, wood will change from a hard to soft density over a small fraction of an inch. This change in density affects the way the drill bit goes into the wood. The drill bit will seek to go into the softer part of the wood. With a HSS bit, the bit may wander seeking a soft spot, and then when it has entered the wood it will tend to flex away from the hard grain. This results in inaccurate holes. Carbide bits also wander, and if they wander when in a drill press, due to the rigidity of the bit either the wood will move, or the bit will break. It seems odd, but I have broken more carbide bits when drilling into wood than any other type of bit.

Cobalt bits, with their split point, are virtually wander-free. Like other bits, once the bit enters the wood it will want to follow the softer grain, but this can be compensated for with proper drilling technique.

Drilling Technique

When drilling into wood, there are three techniques that greatly improve accuracy. First, expose only the amount of the bit needed to drill the hole — leave the rest inside the drill chuck. This minimizes the opportunity of the bit to flex (or break). Second, run the drill at full speed (1,500 rpm on a drill press)3, but enter the wood slowly. This helps to make a clean entry hole, and minimizes drill bit wander and flexing. Next, drill about half way in, pull the bit out enough to clear the debris from the drill bit flutes, and then finish the hole. The pine sap limits the ability of the flutes to clear the debris. If you don’t clear it, it can jam up, resulting in an inaccurate hole and/or an overheated bit.

Pro-Body Tool

When drilling holes with a Pro-Body Tool/Jig, make sure the tool is clamped tightly to the block and the block is clamped in place. Then, making sure that the bit is parallel to the hole in the tool, spin the drill up to speed and enter the wood slowly. Drill about halfway in, pull the drill bit back to clear the flutes, and then complete the hole.

Drill Press

When using a Drill Press, use an accurate fence to stabilize the block and set the offsite from the bottom of the block. Squeeze (or clamp) the block to the fence, then enter the wood slowly, clear the flutes at the half-way point, then complete the hole.

Final Thoughts

Drilling accurate axle holes is a challenge which can be greatly simplified by using the right equipment. When selecting equipment, the type of drill bit is one decision you don’t want to overlook.

1Drill bits are available in four size classifications. The first class, the type in most people’s tool box, is “fractional” (1/16, 3/32, 1/4, etc). The second size class (most popular outside the US) is “metric” (1mm, 2mm, 3mm, etc). The third class is “numbered”. Numbered bits have very small increments and range from “80” (.0135 inches) to “1” (.228 inches). The #44 drill bit used for Cub Scout axles is 0.086, which is about halfway between the 5/64 and 3/32 inch fractional bits. The final drill bit class is “letter”. These bits start after the number “1” bit and range from “A” (.234) to “Z” (.413)

2Beginning in October 2011, the #44 bits sold by Maximum Velocity are Cobalt Split-Point drill bits.

3For Dremel type tools, run on a low to medium speed.

Pinewood Derby Car Showcase

Space Buggy & Flash of Night – Jim White

My grandson (Aaron Shain) and I built these two cars for his 2011 racing campaign. I hope Aaron’s hard work pays-off at the finish line.

American Flag & Ben 10 – Scott Moran

My oldest boy (Shane – 11 years old) designed the American Flag car. My youngest boy (Matthew – 8 years old) designed the Ben 10 car. Shane took 1st and Matthew took 2nd in their pack. The boys cut their cars, sanded the body, applied the wood putty, and primed and painted the cars with my airbrush equipment (the high shine comes from using PPG Deltron basecoat clearcoat). I could go on and on about the paint jobs because they did an awesome job. I have been custom painting and airbrushing for 25 years and my wife and I taught the kids to write their names with an airbrush.

Midnight – Lee Klinghoffer

This is my first foray into Pinewood Derby car-building since I was 11 — now I’m 48. I entered this in my son’s pack race in the “Open” category. It weighed in at 16.1 ounces! Everything else is stock except for the homemade speed axles. I cut 2 v-shaped grooves in them and polished to a high sheen. The car took 1st Place and a new track record.

Q&A

Our pack track was apparently purchased about 10 or 12 years ago and is made of plywood. It’s very nice, smooth and fits together very well. But the braking section is totally inadequate (cars get damaged). Do you know of anybody (or maybe your company) that could put together a real nice braking system for this track?

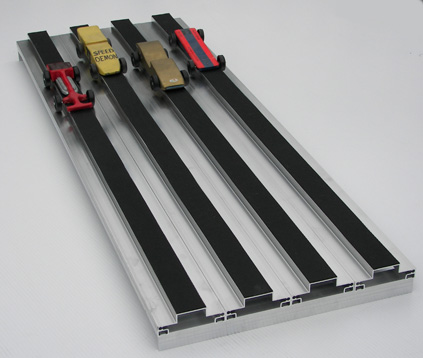

I don’t believe you could find an off the shelf braking system, since your track is likely a custom size, but it should be fairly easy to make a braking section. Usually it is 4 feet long, with guide rails 2 to 3 times taller than the standard rails. The section is setup so that the top of the braking section rails are evenly aligned with the top of the regular rail. So when the car enters the braking section the car’s belly drops onto the raised rail. A rubber strip is attached to the top of the braking section rail, so the cars stop quickly. It would be similar to this one for the BestTrack aluminum track.

You just have to make sure that the braking section rails are spaced exactly the same as on the final section of the track.

We were wondering if you’ve ever done an analysis of how much distance in inches that a difference in time equals (on a 32 foot track). For example, if one time is 2.5200 and the next is 2.521, what would that be in inches?

The problem with making the calculation is that the car is not maintaining a steady speed over the full course. You can make an estimate assuming the speed is constant, but it will be overstated because the car is slowing down at the finish line.

The 2.5 second times you are quoting are similar to the times on my aluminum track. The actual length of my track in inches is 355.5. So if the track is covered in 2.520 seconds, then the car is traveling at a rate of 0.141 in/msec. Thus, it crosses the finish line about 0.141 inches ahead of a car that finishes in 2.521 second. This is just over 1/8 inch. However, in reality the car is going slower. So the difference in inches is less — probably 1/16 inch.

Want Answers?

Do you have a pinewood derby-related question? If so, e-mail us your question.We answer all questions by e-mail, but not every question will appear in the Q&A section of the newsletter.

Back Issues

Are you a new subscriber, or have you missed some of the previous newsletters? Don’t miss out; all of the issues for Volume 5 through Volume 17 are posted on our web site.

Newsletter Contributions

We welcome your contributions. If you would like to contribute an article, a web site review, a speed tip, or a pinewood derby memory, please e-mail us.

Subscription Information

The Pinewood Derby Times is a free e-newsletter focused on pinewood derby racing. It is published biweekly from October through March.

If you haven’t already done so, please forward this issue to your pinewood derby friends. But please don’t subscribe your friends. Let them decide for themselves. Thanks.

If this newsletter was forwarded to you, why not subscribe to receive this newsletter. There is no cost, and your e-mail address is safe, as we never sell or share our distribution list.

To subscribe, send a blank e-mail to

[email protected]

You will receive a confirmation e-mail. Reply to the confirmation e-mail and you will start receiving the Pinewood Derby Times with the next issue.

Randy Davis, Editor, Pinewood Derby Times

E-Mail: [email protected]

(C)2018, Maximum Velocity, Inc. All rights reserved. Please do not reprint or place this newsletter on your web site without explicit permission. However, if you like this newsletter we grant permission, and encourage you to e-mail it to a friend.

Maximum Velocity disclaims any personal loss or liability caused by utilization of any information presented in this newsletter.

The Pinewood Derby Times is not specific to, and is not affiliated with the Boy Scouts of America, YMCA, Awana, or any other organization.

(R)Maximum Velocity is a registered trademark of Maximum Velocity, Inc.

(R)Pinewood Derby is a registered trademarks of the Boys Scouts of America.

(R)Awana is a registered trademark of Awana Clubs International.

All other names are trademarks of their respective owners.